As the demand for energy storage solutions grows, understanding the automation processes involved in module and pack assembly becomes vital for battery energy storage system suppliers. Efficient assembly processes enhance production rates and ensure quality, making it essential for suppliers to familiarize themselves with available technologies and techniques.

The Importance of Integrated Line Solutions

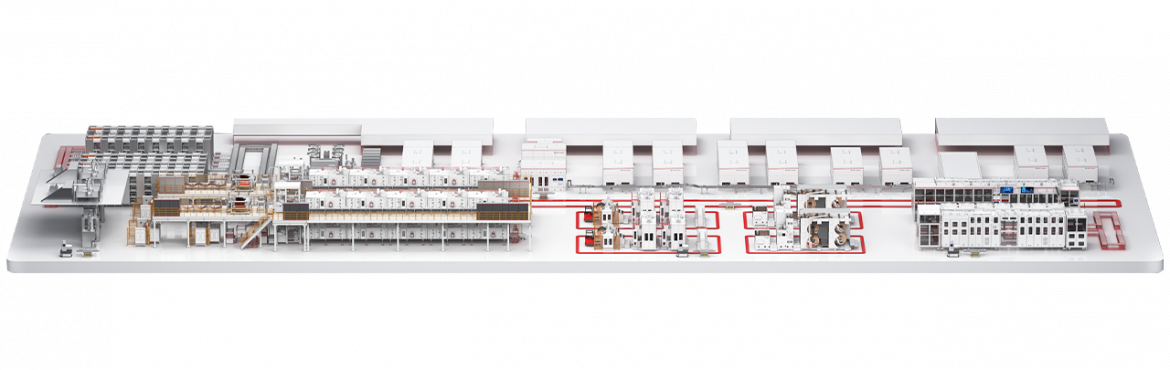

Integrated line solutions are key to optimizing battery manufacturing processes. These comprehensive systems facilitate various stages of production, from cell assembly to final packaging. Leading suppliers like Yinghe specialize in providing integrated line solutions tailored to different battery types, including prismatic and cylindrical batteries. By leveraging their expertise and extensive practical experience gained from over 40 integrated line cooperation projects, suppliers can streamline operations while maintaining high standards of safety and reliability.

Customization for Specific Manufacturing Needs

Battery energy storage system suppliers often require customized solutions to meet specific operational requirements. Yinghe offers tailored options for winding and stacking processes, as well as integrated line and single machine customization. This adaptability enables suppliers to choose solutions that best fit their production workflows, enhancing efficiency and product consistency. Additionally, emerging technologies like solid-state and sodium-ion batteries showcase the evolving landscape of battery manufacturing, which requires flexible assembly automation strategies.

Embracing Smart Factory Solutions

The future of battery manufacturing lies in smart factory solutions that incorporate advanced automation and data analytics. By integrating IoT-enabled devices and real-time monitoring systems, battery energy storage system suppliers can gain valuable insights into production efficiency, maintenance needs, and quality control. Such technologies not only optimize assembly processes but also assist in making data-driven decisions for continuous improvement.

Partnering with Yinghe for Enhanced Automation Solutions

For battery energy storage system suppliers seeking to enhance their assembly automation capabilities, partnering with Yinghe is a strategic choice. With their commitment to providing intelligent lithium battery production line solutions and expertise in emerging battery technologies, Yinghe equips suppliers with the tools necessary to thrive in a competitive market. By choosing Yinghe, businesses can elevate their battery manufacturing processes and ensure the delivery of reliable energy storage solutions to meet growing industry demands.